The Hi-Re-Li System

In 1966 while muscle cars still roamed the highways, Jim Harnish, an Engineer at Westinghouse, was working on ways to improve the efficiency of air conditioning and increase the operating range of heat pumps so they could be utilized in colder climates. Also at the time, large computing systems were first being developed which needed cooling year round similar to the large data centers in use today.

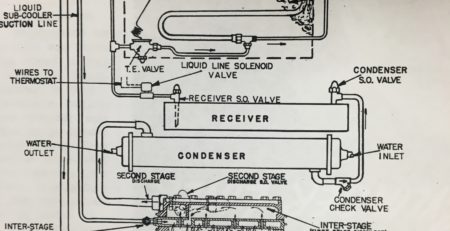

To address these challenges, Harnish developed his Hi-Re-Li system. The highly reliable (Hi-Re-Li) used a unique expansion device which regulated the flow of refrigerant by the liquid sub-cooling instead of the super-heated vapor leaving the evaporator. The thermal bulb on the liquid line leaving the condenser often confused the techs in the field.

The expansion device opened or closed in response to a 10 degree sub-cooling target. The liquid line was in contact with the suction line to the compressor to further sub-cool the liquid. He sub-cooled the liquid line even more in a special suction accumulator with a heat exchange.

The suction accumulator was key to the operation of the Hi-Re-Li. It used a special “pancake” coil, a flattened helix concentrated at the bottom of the tank so that it would be constantly covered with liquid. Harnish wanted to increase the wetted surface of the evaporator to increase the efficiency. So, he flooded the evaporator with liquid. The suction accumulator prevented flood back of the saturated refrigerant leaving the evaporator to the compressor, the sub-cooling “pancake” heat exchanger coil helped evaporate the liquid in the suction gas.

The expansion device which regulated the sub-cooling allowed it to operate for cooling over a greater range in ambient temperature without needing extra head pressure controls on fan cycling. For heat pumps on the heating cycle, the compressor operated at a lower discharge pressure and suction pressure so that it could continue to provide heat at ambient temperatures as low as -20 degrees Fahrenheit.

Over the years, Refrigeration Research made many of these special suction accumulators with the “pancake” coil and we continue to make them for the Paul Mueller Company which bought the license to the technology many years ago. The sight of the thermal bulb on the liquid line continues to baffle some techs in the field even today.