Suction Accumulator – Commercial

- Description

- Specifications / Application Data

- Installation & Downloads

Description

The ORIGINAL, TIME TESTED SUCTION ACCUMULATOR

Air conditioning, heat pump, truck refrigeration and many other applications require intermittent operation of the refrigeration compressor. Especially in remote applications, the suction line may trap or hold quantities of liquid which are suddenly dumped into the compressor as it starts up. This is frequently the cause of broken valves, pistons, broken or bent connecting rods, blown gaskets and bearing washout. Proper installation of the Refrigeration Research suction accumulator in the suction line, just before the compressor, eliminates damage. If correctly sized, relatively large quantities of liquid refrigerant may return through the suction line and the suction accumulator prevents damage to the compressor. Liquid is temporarily held in the suction accumulator and metered back to the compressor along with any oil, at a controlled rate, through the metering orifice. Therefore, damage to the compressor is prevented and the compressor immediately and quietly goes to work.

THE ORIGINAL, YET IMPROVED, SUCTION ACCUMULATOR BY REFRIGERATIONRESEARCH PROVIDES ALL OF THE IMPORTANT FEATURES.

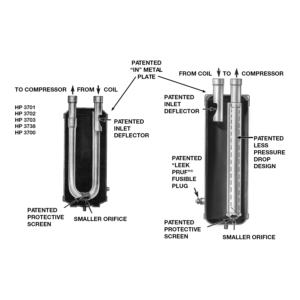

- Exclusive (patented) inlet deflector for improved performance. Deflector permits tangential entry of fluid.

- Marking of inlet with a metal plate is an exclusive feature and helps prevent errors in hook up.

- All Refrigeration Research suction accumulators of 4” through 6” diameter have fusible plugs included and installed to comply with latest

and

and  requirements.

requirements. - Copper nipples are standard on vertical

and

and  models.

models. - Controlled hydrogen copper brazing process provides the ultimate in cleanliness and uniform strength.

- All Refrigeration Research suction accumulators are

and

and  listed or built to ASME code, CE documentation also available.

listed or built to ASME code, CE documentation also available.

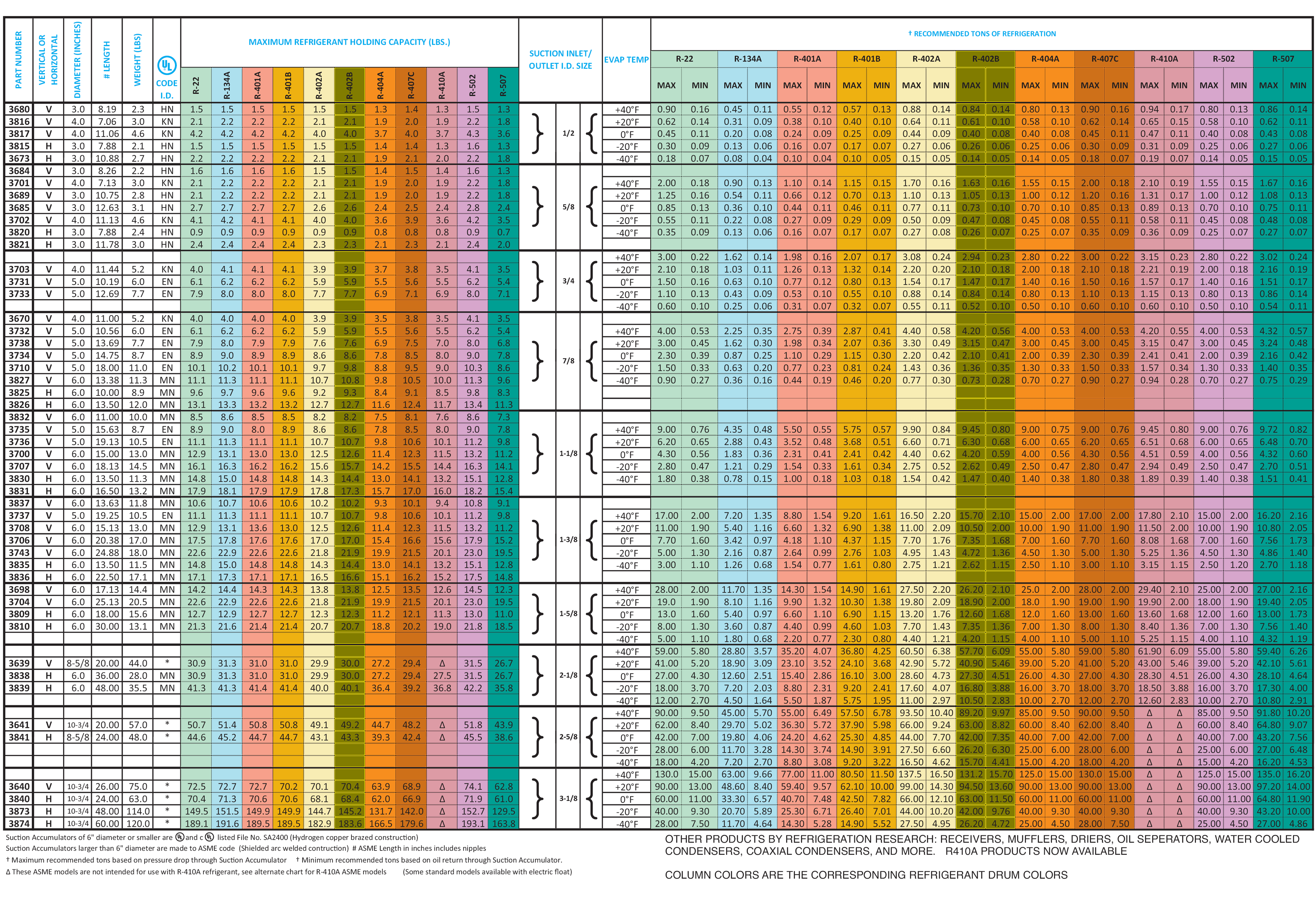

Suction accumulators by Refrigeration Research have been field proven in hundreds of thousands of installations. SELECTION OF SUCTION ACCUMULATOR – The suction accumulator should not necessarily be selected to have the same size inlet and outlet as the compressor suction line. It is more important to select the suction accumulator well within the limits of (1) pressure drop, (2) oil return as shown on the following page and (3) total amount of charge to be held.

The actual refrigerant holding capacity needed for a suction accumulator is governed by the requirements of the particular application. There is a great variation in refrigeration systems and this must be considered. Where possible the capacity selected should be checked by actual test. Normally the accumulator should not be sized for less than 50% of the total system capacity. If in doubt, consult the compressor manufacturer. Steel nipples are available on special order.

PATENTED NO. 5,076,313 AND PATENTS APPLIED FOR.

SUCTION ACCUMULATOR

Cannot Trap Oil

PURPOSE - To prevent compressor damage due to the sudden return of liquid through the suction line.

Compressors on many air-conditioning, truck, heat pump and other refrigeration systems are often subjected to sudden liquid return, resulting in broken valves, pistons, connecting rods, crank-shafts, blown gaskets or bearing failure.

Compressors on low superheat applications such as liquid chillers, low temperature display cases and truck refrigeration are especially susceptible to damage from liquid refrigerant.

THE SUCTION ACCUMULATOR, by Refrigeration Research will protect the compressor. Although several pounds of refrigerant may suddenly return through the suction line it does not flood into the compressor. The liquid refrigerant is temporarily held in the suction accumulator and metered back to the compressor at a controlled rate, through the metering orifice.

ACTS AS A SUCTION MUFFLER - In most cases it will be found that the suction accumulator also reduces transmission of noise to the low side since it tends to act as a suction muffler.

LOCATION - The suction accumulator should be installed in the suction line as close to the compressor as possible. In reverse-cycle systems, it must be installed in the suction line between the compressor and reversing valve.

MOUNTING POSITION “Vertical” Accumulators must be installed vertically. “Horizontal” Accumulators must be installed horizontally.

INSTALLATION - It is MOST IMPORTANT that the INLET and OUTLET of the suction accumulator be correctly connected. The “IN” stamped at the top must be attached to the suction line from the coil and the “OUT” must be attached to the suction line leading to the compressor. Otherwise, oil and refrigerant would be trapped. If the connections are made correctly the suction accumulator cannot trap oil.

MAKING CONNECTIONS - A good quality of silver solder should be used for making connections. Silver solder No. 45 or No. 35 may be used. Good practice dictates that the suction line should properly fit the accumulator nipples and a good joint should be made without causing flux and silver solder to run into the accumulator. A good joint can easily be made if a flame of correct size and intensity is used. Under no circumstances should connections be made with so-called “soft solder” such as 50-50, 95-5 etc. which does not have sufficient strength to withstand vibration of the suction line at the compressor. All connections on ![]() vertical and

vertical and ![]() model accumulators with copper nipples can be made with a silphos or equivalent alloy.

model accumulators with copper nipples can be made with a silphos or equivalent alloy.

PROTECTING JOINTS - After solder joints have been carefully leak tested, nipples should be painted with “Rust-O-Leum” or equivalent to prevent rust.

SELECTION OF SUCTION ACCUMULATOR - The suction accumulator should not necessarily be selected to have the same size inlet and outlet as the compressor suction line. It is more important to select the suction accumulator well within the limits of (1) pressure drop and (2) oil return. Total amount of charge to be held (3) is also important.

The actual refrigerant holding capacity needed for a suction accumulator is governed by the requirements of the particular application. There is a great variation in refrigeration systems and this must be considered and where possible the capacity selected checked by actual test. Normally the accumulator should not be sized for less than 50% of the total system capacity. If in doubt, consult the compressor manufacturer.

CONSTRUCTION - The suction accumulator is constructed entirely of steel. Hydrogen copper brazing insures the ultimate in cleanliness, strength, and durability under vibration. Vertical ![]() and

and ![]() models are manufactured with copper nipples.

models are manufactured with copper nipples.

SUCTION ACCUMULATORS PROVIDE LOW COST INSURANCE - They are easily and quickly installed and when properly applied will provide years of trouble free service. When the possibility exists

of compressor damage through sudden liquid return, the low initial cost of the suction accumulator may be saved many times over by increased compressor life.